Alumina ceramics is a ceramic material with Al2O3 as the main crystal phase. SENCERAMCS can produce ceramic products with an alumina content of 96% to 99.8%. The alumina has a compact structure, low activity, and high-temperature stability. The electrical properties are the best, with good mechanical properties, with a Mohs hardness of 9. Alumina 99.8% ceramics have high mechanical strength, high volume resistivity, good electrical insulation properties, high lightness, and wear resistance. A series of anti-oxidation properties are widely used in structural parts and functional device ceramic parts, such as wear-resistant and corrosion-resistant parts used in the mechanical and chemical fields; crucibles, protective tubes, refractory materials used in the metallurgical industry; substrates, insulators, Porcelain parts for the electronics industry, such as radomes, microwave electrolytes, etc.

99.8% Alumina Parameters

| Composite | (wt %) | 99.8% |

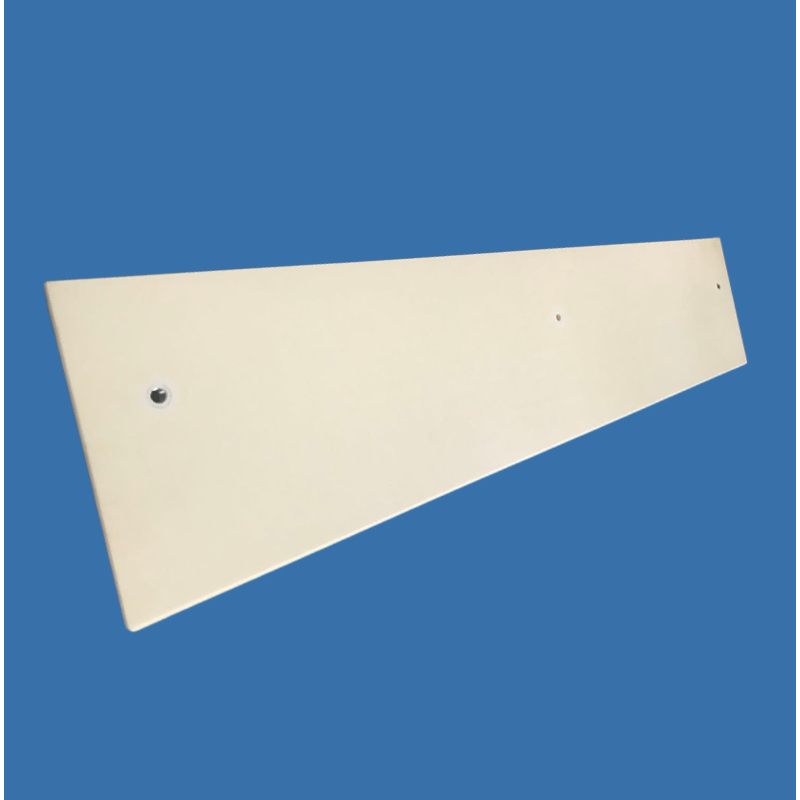

| Color | Ivory | |

| Density | g/cm3 | 3.92 |

| Hardness | HRA | 85 |

| Flexural Strength | Mpa(psi*103 ) | 381 |

| Gas Permeability | 0 | |

| Water Absorption | % | 0 |

| Thermal Shock Resistance | °C | 198 |

| Thermal Expansion | ×10-6/℃ | 8.2 |

| Dielectric Constant,20°C | 1MHz | 9.7 |

| Dielectric loss, tanδ | 1MHz | 1×1014 |

| Volume Resistivity,20℃ | Ω·cm | ≥1014 |

| Dielectric Strength,DC | Ω·cm | 20 |

| Compressive Strength | KV/mm | 2600 |

| Fracture Toughness | MPa( psi * 103) | 350 |

| Poisson’s Ratio | MPa | 0.22 |

| Thermal conductivity | W/mK | 27 |